This post is?going?to discuss some adjustable/prefixed torque wrench, screwdriver, and limiter etiquette that you may not have known or forgetten about.

First, Before you use your torque tool for the day, make sure to break?it at its max or prefixed value six times.? This helps loosen up the tool to perform at the calibrated accuracy.

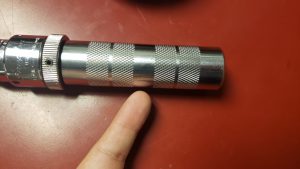

Secondly, when applying torque, make sure you apply pressure from the middle of the handle. This is?sometimes indicated by the manufacturer (example pictures below).? If you apply torque to a different part of the torque wrench, you will cause stress and torque to build?in?places that the torque wrench was not designed to have.? The added stress causes more wear on your tool and can lead to incorrect torque to be applied for the job.

Next,? you want to apply torque in a smooth action.? Applying torque in a quick/snappy way can likely make you over torque the your bolt, nut, screw, or adapter.? If you apply it too slow, it can cause the torque wrench to break prematurely not giving you the proper amount you may need.

Also, make sure that when you are done using your adjustable torque tool,?to set the value to the lowest setting that the manufacturer has indicated.? If you leave the torque wrench set at a higher value, you will cause extra wear and tear on your tool which can effect the accuracy over time.??The torque wrench is not designed to be set lower than what is indicated and can cause inaccurate torque values.

Lastly,? to easily calculate from one torque value to another, here’s helpful list to guide you.

16inoz=1inlb; 12inlb=1ftlb, 1ftlb=192inoz.

?I hope you found this post informative?and the information you learned will help prolong the life of your tools.? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?